Ok, now it's time to install the shifting.

Grease up the derailleur and screw it in; Grab the 12-speed chain, install the 46T QXL ring, and test our swanky new 1x12 drive train. Simple right?

Errrrr nope, At some point, any build with brand new tech goes pear-shaped and biking gods saw me coming.

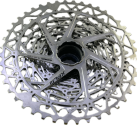

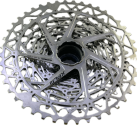

The time gap between the first and second photos here was 4.5 hours. Here's what I learned so you don't have to.

1. The new 12spd 1x12 stuff from SRAM doesn't like to shift without load, so it's tough to tun on the bike stand. You should set the upper and lower limits and be done. Don't waste an hour of your time like I did it will run fine. 1x12 depends on the tiny motions to get the cassette to grab the chain and then pull the derailleur into place via the chain; it's will allow that motion for 20 seconds after the shift; if it doesn't move by then it return to the previous position. On the stand without load this feel like "no shift" because the chain doesn't bite into the cassette.

2. The APEX is nice and ALOT cheaper than Eagle but has no clutch, but it does have a spring made by Demon just like Eagle to don't plan on installing your quick links while it's mounted on both the ring and the cassette you'll kill your hands

3. 1x12 uses the same chain length as normal bike size by going around both big rings just like Sheldon taught you. See:

www.sheldonbrown.com/derailer-adjustment.html#chain

If you are using an APEX 44T you have to get it perfect because of the tolerance the derailleur can't take up extra via the b-screw

4. The APEX will hit and have hard interference with the 44T no matter what you do; without a chain install you have to stay out of the first 3 derailleur positions

5. Short chain lines suck for 1x12. The angle of attack is too steep, and the chain will fall off of the front ring if it's too big due to the angle. I have a subpar chain, it's 12-speed but was also missing quick links from the package so I'm using 11sp ones. I was too cheap to buy the weird SRAM flat-top chain. (That will be here from amazon later today to correct my error.)

6. I tried to use a 46T QXL ring first from a 2x setup. Didn't work. Too big, it created a huge attack angle and lacks the special 1xN design and long teeth to handle the attack angles. Tried if forward without the bash shield. That was dumb. Tried it mounted backward was dumber, forgot about the teeth being shaped to match the orientation. Tried it normally again with the bash guard. Work until I did anything aggressive for a backspin at which time the chain would just pop off.

7. Finally settled on an inner QXL chain ring, a 36T with the bash guard, where the Stock e-ring from Cruzbike almost worked; this one actually did work. It has issues but good for a week or two.

8. I will have to repeat all these tests with the SRAM chain but for this tiny chain stay and all the different ring sizes, that means having the time to shorten the chain tested the biggest 46T ring and work down to the E-ring and finally to the 36T. I suspect having a Rotor 1x chain ring would make a big difference, but I don't have one and trying to avoid that $180.