brokemyback

Well-Known Member

I have a new (used) V2. When I got it, the headset was adjusted “properly” with no perceptible lateral slop. However there was so much rotational friction the bike was almost unrideable! I have many miles on my Silvio, so I know I’m not the problem.

I have tried many different preloads with the same result. To eliminate the rotational friction I must adjust the headset to be pretty loose, with a fair amount of slop (rocking the bike with front brake applied).

Questions:

1. The slop isn’t particularly bothersome to me, but will I hurt the head tube of the frame by riding like this?

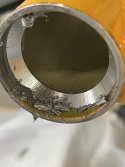

2. The headset bearings feel very smooth, no perceptible play or wear. I see one thin shim under the dust cap, so I did a test that removes the dust cap from the stack up - resulting in no improvement of the friction problem. Got any ideas why I get so much rotational friction when I adjust the preload “properly”?

I have tried many different preloads with the same result. To eliminate the rotational friction I must adjust the headset to be pretty loose, with a fair amount of slop (rocking the bike with front brake applied).

Questions:

1. The slop isn’t particularly bothersome to me, but will I hurt the head tube of the frame by riding like this?

2. The headset bearings feel very smooth, no perceptible play or wear. I see one thin shim under the dust cap, so I did a test that removes the dust cap from the stack up - resulting in no improvement of the friction problem. Got any ideas why I get so much rotational friction when I adjust the preload “properly”?